MANURE MANAGEMENT

Livestock equipment AND MANURE MANAGEMENT

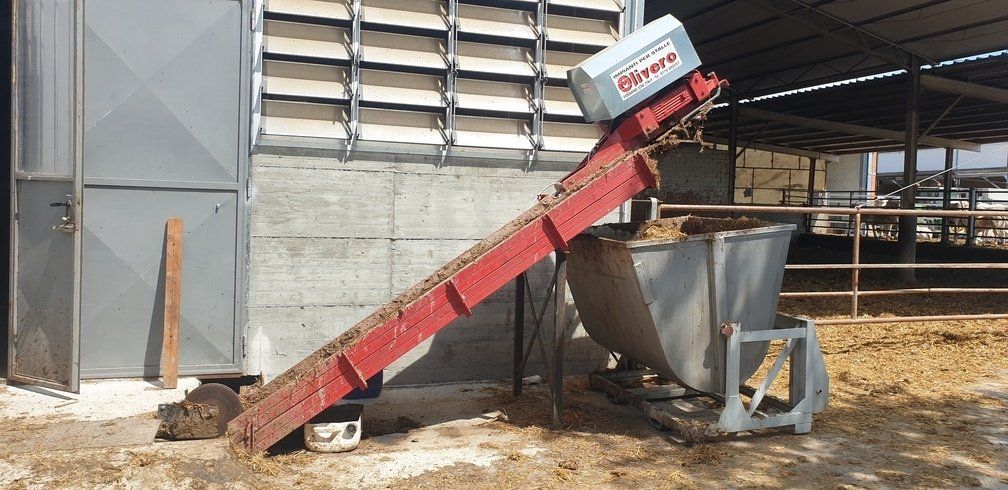

It is a closed circuit system, necessary for cleaning in stables of: cattle, horses, rabbits, chickens and pigs. The movement of the chain takes place by means of a suitably sized reduction unit, connected to an electric motor, the chain sliding in a channel carries the manure on an elevator which reaches the top and unloads it on a dumper or in a fertilizer.

The chain is supplied in three models:

- P.18 with normal iron U-bolts P.20 with 200Mg Cr5 alloy U-bolts P.22 with welded blades

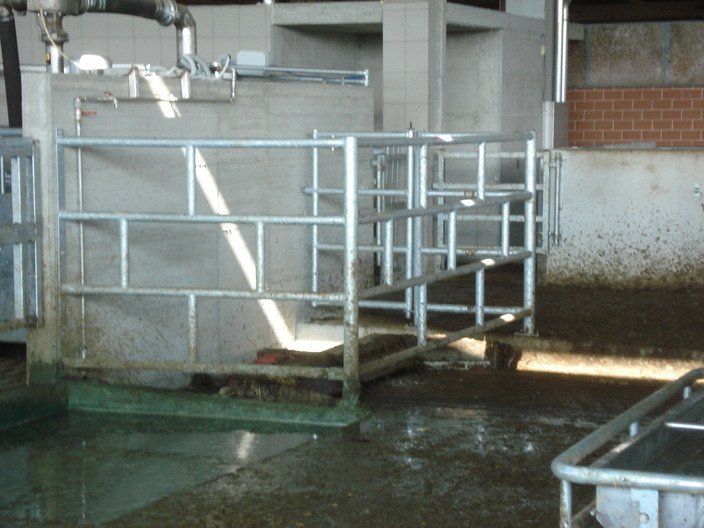

The plant consists of 3 main components:

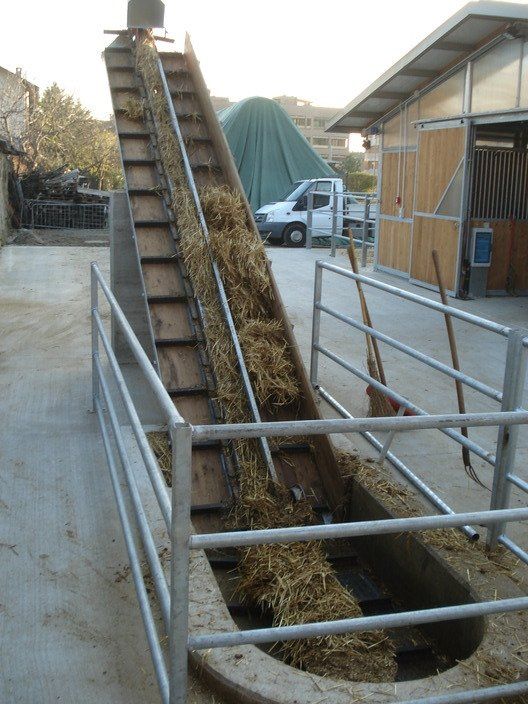

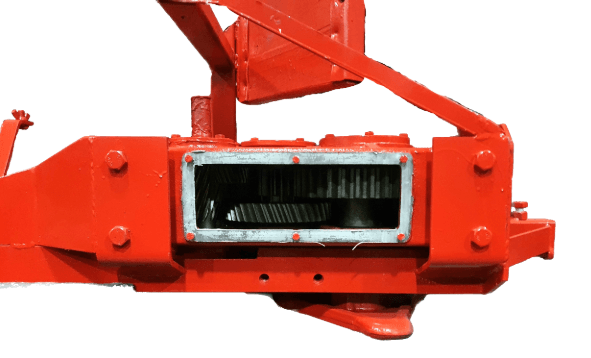

ELEVATOR

Hot-dip galvanized or painted electro-welded iron structure, it can have various lengths and widths according to the system in which it will be installed. The channels are covered with larch wood beads, on request they can be covered with stratified panels or stainless steel.

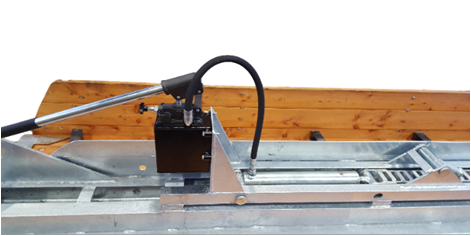

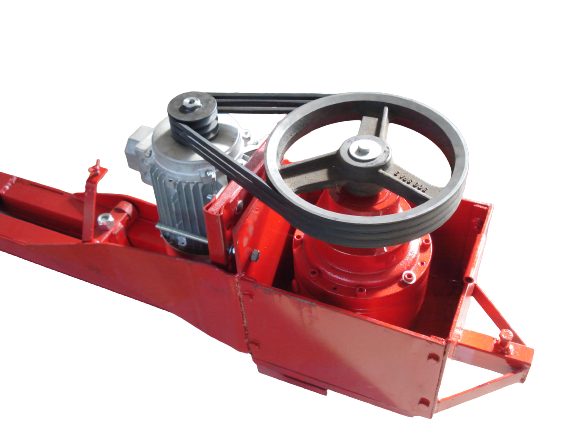

TOWING GROUP

The chain is driven by means of a reduction unit located at the upper end of the elevator.

This group is sized according to the size of the system

Here are some of our gear units:

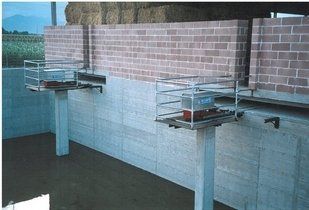

CHAIN and CHANNELS

The chain we produce is a flat steel link chain.

we have 3 types, in order to best size the latter to the required system.

The chain runs inside a concrete channel, in which the pins and curves produced by us are walled, in such a way as to be able to turn the chain inside the barn.

Accessories can also be installed in the channels to make the system more functional and less hindering the animals.

CAV AND SHEET PANELS

For the coverage of the channels we have two types of infill:

- with prefabricated CAV shelves with embossed, painted or galvanized steel sheets

The choice between the two types is up to the customer, as both are valid solutions to allow the passage of vehicles and livestock

OPENABLE SHEETS

These sheets are used when there is a combination of scraper and manure removal system.

These sheets, thanks to a hydraulic or varicello system, allow the transit of tractors when the scraper system is stopped, while when it is in operation they allow the scraper to unload the manure into the channel of the manure remover.

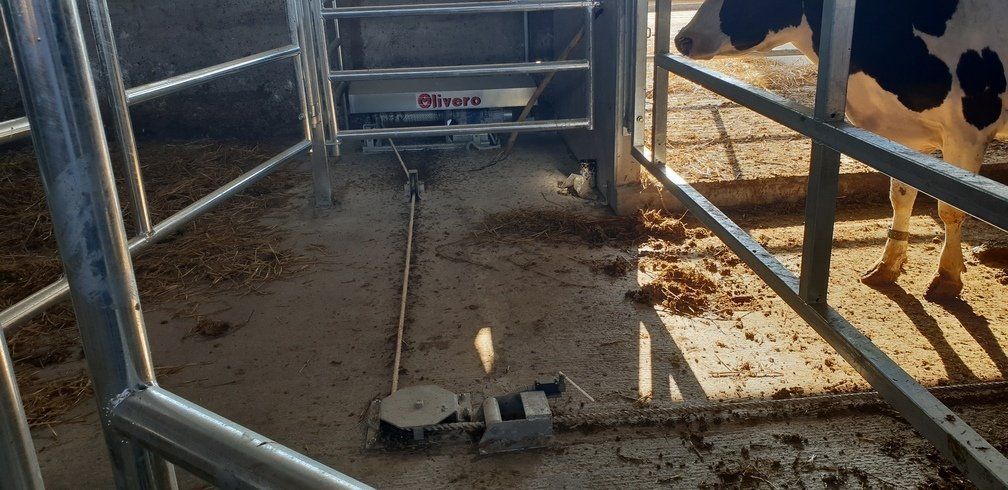

CHAIN SCRAPERS

It is a closed-circuit system, necessary for cleaning free-stall cowsheds, in which a reduction unit generates movement to a catenary, which, running in a channel, placed in the center of the lane, to be cleaned, drags a scraper, which pushes the liquid manure to the end of the aisle. The scraper can be fixed, flap or delta.

ROPE SCRATCHERS

This plant is composed of two towing units which, by means of a high tenacity polyester rope, alternately generate the movement of the scraping blades, which transport the liquid manure to the end of the barn. Available with an electronic panel that determines the cleaning frequency and the calibration of the removable weight. This type of system has the advantage that it does not require masonry work for placement.

HYDRAULIC SCRAPERS

Consisting of a piston which, through a control unit, generates the movement of an iron rod U, which slides inside a special channel, placed in the center of the lane to be cleaned. The shaft performs an alternating motion which, by means of the slots obtained on the back of the same, generates the sliding of the scraper and the dragging of the manure to the end of the barn, after which through a special deviator it performs a reverse movement and returns to the starting position .

SPECIAL SCRAPERS

On request, we design scrapers for transporting sewage and various types of waste, based on the specific requests of the various systems to be satisfied.

Some special works made by us: